Sappi Maastricht orders 20MW Electrode Steam Boiler

PARAT will deliver a modern 20MW Power to Heat system with Zero-Load to the Dutch Paper factory, with delivery in Q4 2022.

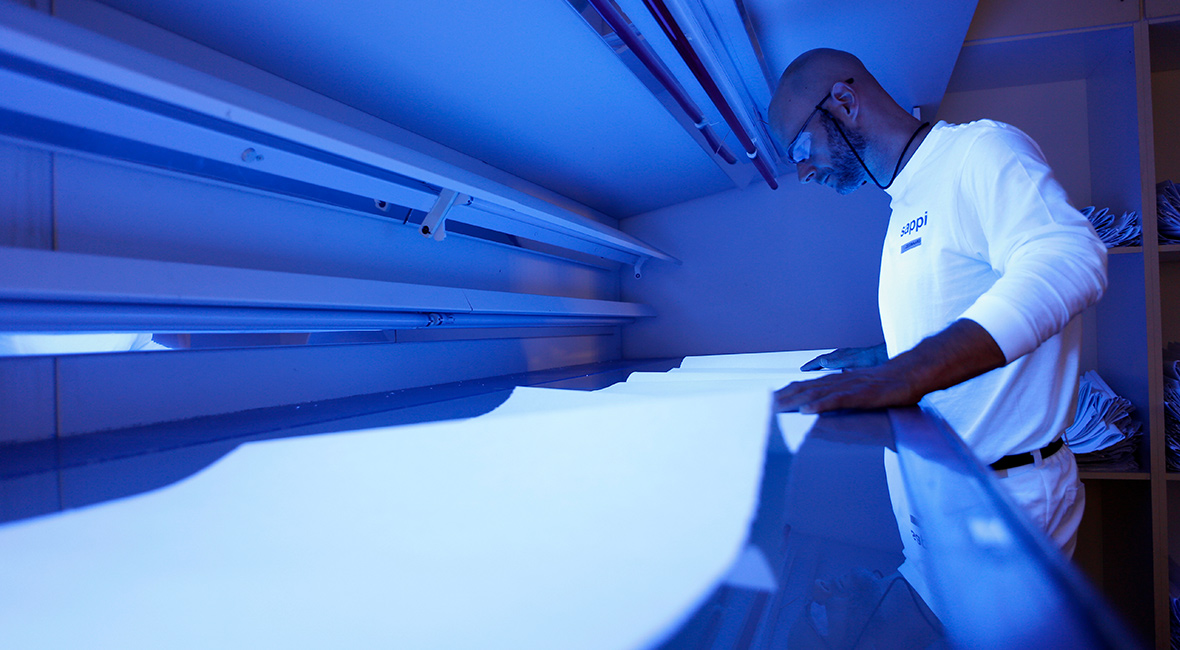

Located in the Netherlands, Sappi's Maastricht Mill uses certified, renewable raw materials to produce high-quality products that are completely recyclable. (Photo: Sappi)

Located in the Netherlands, Sappi's Maastricht Mill uses certified, renewable raw materials to produce high-quality products that are completely recyclable. (Photo: Sappi)

Sappi have ordered a 20MW High Voltage Electrode Steam Boiler from PARAT. Technical specs are: 10kV connection, 18 barg Design Pressure and 210°C Design Temperature and will be delivered with Zero-Load option for grid regulation. Sappi Maastricht was one of the plants that was granted SDE++ Subsidies in the Netherlands in 2021.

PARAT will also deliver the Control panel, pumps, valves and dosing system. The project in Maastricht will be done together with ECO Steam and Heating that will do the installation of the boiler on site.

Sappi Maastricht

Located in the Netherlands, Sappi's Maastricht Mill uses certified, renewable raw materials to produce high-quality products that are completely recyclable.

Maastricht Mill is a paper producer that deploys a high-quality production process and continues innovation to create a leading product in terms of quality. In this, sustainability and respect for people and the environment are paramount. We use certified, renewable raw materials and our products are completely recyclable.

Sappi Press Release 25.02.2022:

Sappi drives decarbonisation with the installation of a new e-boiler at its Maastricht Mill

As part of a long-term global commitment to sustainability and climate protection, Sappi is actively planning the extensive modernisation of the current steam generation boiler at its Maastricht Mill in the Netherlands. With an investment of close to 6 million euros, the mill’s yearly emissions of carbon dioxide will be reduced by some 13 per cent (compared to 2019) following commissioning. This represents a reduction of 22,000 tons of carbon dioxide annually. The reduction in CO2 emissions will be achieved by replacing part of the gas generated steam by electric generated steam via a newly to be installed e-boiler. The electricity used will be generated through renewable energy sources such as solar power and wind energy.

'The e-boiler project represents a key milestone in our plans to future-proof the Maastricht Mill', explains Ferdinand Koster, Mill Director Maastricht at Sappi Europe. 'The installation of the e-boiler will ensure a significant reduction in CO2 emissions. And it brings us a clear step closer to achieving our sustainability targets for the mill by 2025 within the framework of Sappi’s decarbonisation roadmap.'

Sappi’s decarbonization roadmap includes 2025 targets to achieve a reduction of specific greenhouse gas emissions (scope 1 and 2) by 25 percent and increase renewable energy share to 50 percent in Europe compared to 2019.

The project, set for completion in December 2022, will contribute to Sappi’s ambitious decarbonisation targets and continued commitment to ensuring a sustainable, low-carbon future – as determined by the Paris Climate Accord and the European Green Deal.

More information