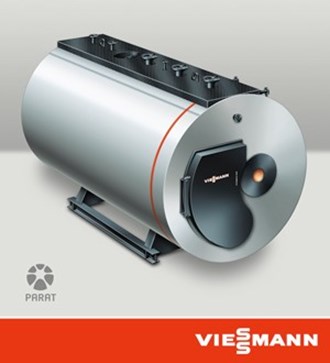

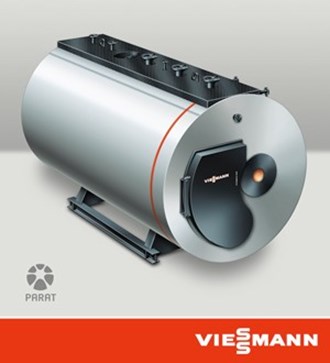

VITOMAX 200-HS M73A

High Pressure Steam Boiler 0.5 - 4.0t/t, 6-25 bar

- High pressure steam boiler with steam output from 0.5 to 4 t/h

- Three-pass boiler – clean combustion with low nitrogen oxide emissions

- Insensitive to load fluctuations

- High steam quality due to large steam chamber, large evaporator and an integral steam drier

- Economical energy consumption

- Low radiation losses due to 120 mm composite thermal insulation and water cooled burner feed-through

- Low pressure drop on the hot gas side due to convection heating surface with large hot gas tubes

- Load-bearing boiler cover on top of the steam boiler included in the standard delivery – simplifies installation and maintenance and protects the thermal insulation against damage – extendible to platform

- Robust base frame makes boiler foundations superfluous

- Large selection of matching accessories simplifies system integration

- Robust frakt og installasjon beskyttelse, som standard

- Robust shipping and installation protection, as standard

- Approval according to European Pressure Equipment Directive 97/23/EC and/or specific national regulations. By exceeding the minimum requirements set by the FDBR guidelines, Viessmann boilers achieve the longest permissible inspection intervals

With the Vitomax 200-HS (type M73A) high pressure steam boiler, Viessmann meets the requirements of efficient steam generation. The permissible operating pressure extends from 6 to 30 bar. The output range extends from 0.5 to 4 tones of steam per hour. The Vitomax 200-HS is used in manufacturing industries, as well as food processing, fertilizer production, construction materials, paper, beverage, chemical and pharmaceutical industries, hospitals and refineries. Optionally, the high pressure steam boiler can be operated with light fuel oil (HEL), liquid gas or (bio) natural gas.

Reliable design

The spacing between the smoke tubes, as well as from the smoke tubes to the boiler shell and to the flame tube, are well above requirements. The shearing force on the end face floors caused by different linear expansion in the smoke tubes and the flame tube is therefore extremely low, guaranteeing a long service life for these steam boilers. The corner stays of the boiler are always arranged in pairs. As a result, the forces are distributed, reducing the stress in the component and increasing the service life. In every case, the values lie well below the limits permitted by the FDBR trade association.

Flexible application

Customer-specific requirements can be taken into consideration in the design of boilers in this series.

More information